Metalworking Fluid

Having worked closely with the world’s leading metalworking fluid manufacturers, Shell understands the challenges that you face.

We know that to succeed in the competitive global marketplace it is essential to maximise productivity and process efficiency while minimising emissions and improving workplace conditions.

The Shell Risella X range is the next generation of process oils based on gas-to-liquids (GTL) technology. They have been developed to unlock competitive advantage because they offer.

Personal Care

Consumers in the worldwide market for cosmetics and toiletry have become much more sophisticated buyers and expect higher quality products. To be successful, cosmetic producers must meet these demands and offer clear differentiation from their competitors.

In addition, there is a clear trend for consumers seeking purer products and those that are naturally based or nature-inspired. White oils are commonly used ingredients in most types of personal care products and many cosmetics formulations, from petroleum jelly to hair and skin care products.

Shell’s next generation medicinal white oils, Shell Ondina X, are no longer based on conventional mineral oils derived from crude oils, but on GTL technology. Shell Ondina X oils can help you to unlock competitive advantage.

Polymer Industry

Shell understands your business and the challenges that you face. Your products need to match your customers’ needs in a wide range of industries, including the automotive, consumer goods, industrial and medical sectors. Their requirements are becoming more and more sophisticated while legislation becomes more stringent.

Process oils play a critical role in the formulation of polymer compounds and rubber blends. They typically represent 20–50% of a polymer compound, such as TPE, and up to 100 parts per hundred in rubber blends, such as EPDM. The process oil functions as an extender oil, and it is extremely important that it has good performance and compatibility with the polymer as this influences the rubber’s softness, elasticity and colour stability.

Shell Risella X oils can help you to unlock competitive advantage because they offer eXcellent performance and eXtra purity.

Defoamer

At Shell, we understand the crucial role that process oils play in your product and operations. We know that you need defoamer formulations for your customers that offer excellent performance in minimising foam formation, rapidly releasing entrained air, and having low volatility to minimise the potential emission of volatile organic compounds (VOCs).

In oil based defoamer formulations, the oil can comprise up to 90% of the formulation. It functions as a carrier fluid, in order both to spread over the surface of the aqueous system to neutralise the surfactant molecules and to transport the hydrophobic ingredients of the defoamer to the double layers of surfactant molecule that stabilise the foam bubbles in order to destroy them.

Shell Risella X can help you unlocking competitive advantage because it offers eXcellent performance and eXtra purity.

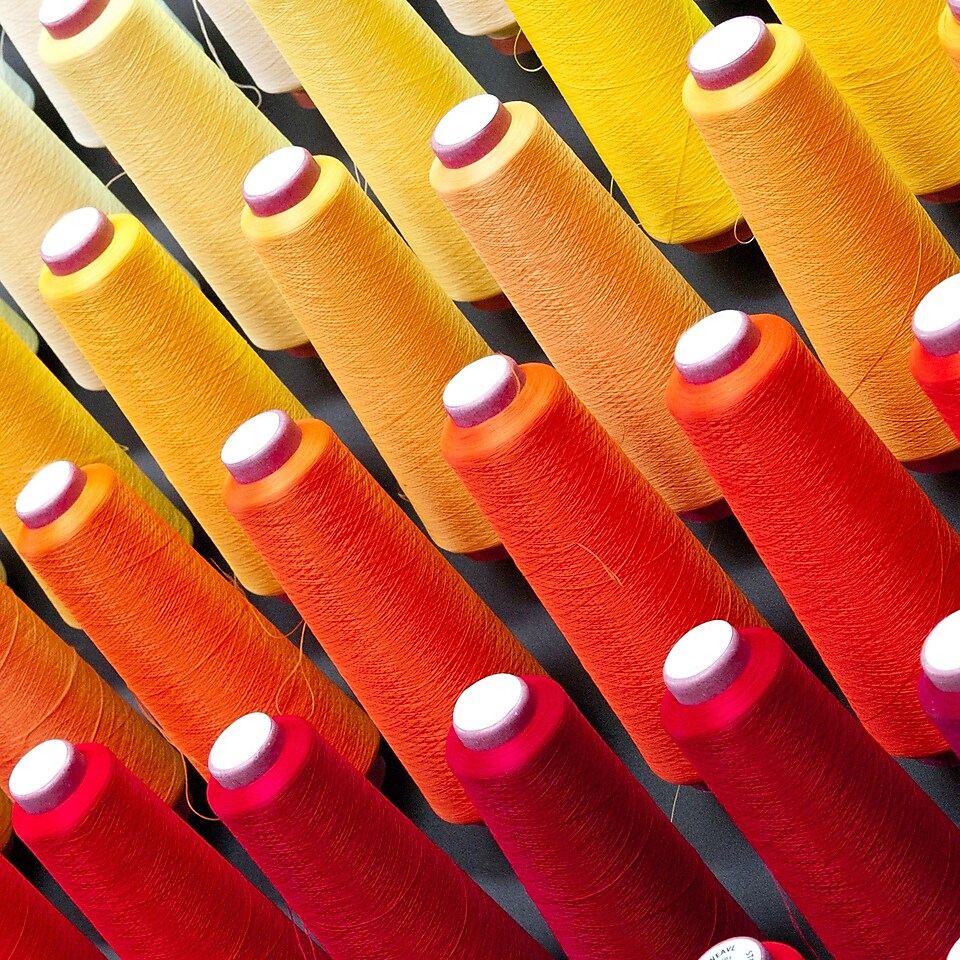

Textile

Textile auxiliary formulations are critical in the manufacturing processes for yarns, nonwoven fabrics and all valuable products made from fibres. They prevent wear and rupture of the fibres, avoid electrostatic charging of fibres and reduce dust formation on fibres and roller points. These formulations can be applied either as an emulsion with water as a spin finish or pure as coning oil.

At Shell, through working closely with the world’s leading textile auxiliary manufacturers, we understand your challenges. We appreciate that to succeed in the competitive global marketplace it is essential to maximise productivity and process efficiency, while minimising emissions and avoiding ageing effects and discoloration of the fibres. The Shell Risella X range is the next generation of process oils based on gas-to-liquids (GTL) technology. They have been developed to unlock competitive advantage because they offer eXcellent performance and eXtra purity.

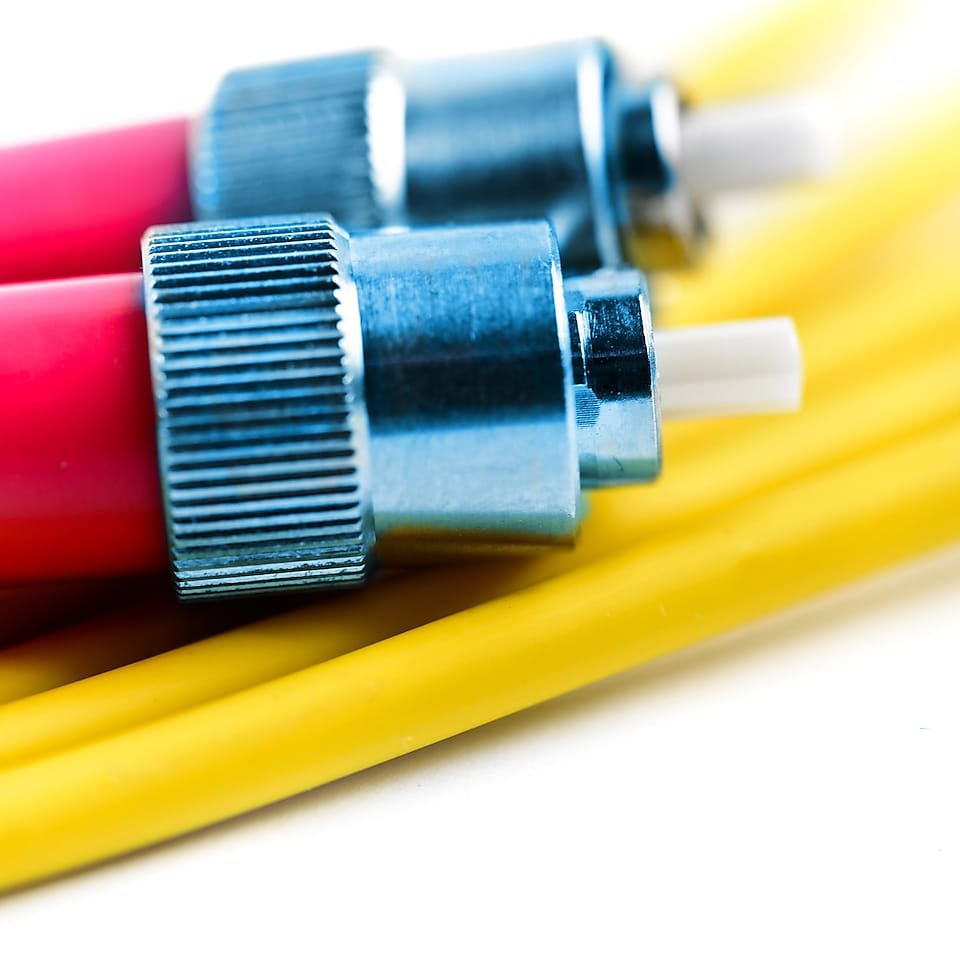

Cable Fill

Kraton and Shell Process Oils have combined their expertise by working together to develop a new generation of optical cable gels that offer gel and cable manufacturers enhanced process efficiency and product quality.

Optical cable manufacturers use an oil-based gel to flood rigid tubes containing optical fibres. These tubes are packed together, flooded with gel again and enclosed in an outer jacket to form the optical cable. The gel needs to display thixotropic behaviour: to flow easily into place under shear but to become viscous once in place to protect the fibres. It must also be free from impurities that could compromise the optical cable’s performance and continue performing by remaining stable and avoiding oil bleed.

“The combination of our polymers and Shell Risella X oils offers an exciting enhancement in process efficiency and product quality with the potential to give both cable and gel manufacturers a new competitive edge.” says Sandrine Duc, Sales Development Manager – Performance Products, Kraton Performance Polymers Inc.

Tyre

Having worked closely with the world’s leading rubber and tyre manufacturers for many years, Shell understands the challenges that you face. Maintaining your competitiveness in the global marketplace requires ongoing product performance improvements, and then there is the ever-present need to adapt to new and emerging legislation.

Shell Flavex 595 is a non-labelled process oil used as an extender oil in the manufacture of tyres. It is made using residual aromatic extract (RAE) technology to produce summer, all-season and high-performance tyres. It offers an alternative to traditional distillate aromatic extract (DAE) products and is fully compliant with EU Directive 2005/69/EC , REACH Regulation 1907/2006, Annex XVII (Item 50).

It presents exciting new opportunities, unlocking competitive advantage for both tyre and styrene butadiene rubber producers. It could also provide a real edge for your products.

Shell process oils can help tyre manufacturers to enhance the performance of their products and meet environmental legislation.

Various manufacturers in the rubber industry have unlocked value by using Shell Flavex 595, as it shows several advantages in applications requesting high polarity.

Other

Process oils are used in a large variety of finished products in the chemical and manufacturing industries.

Shell, with more than 25 years’ experience, recognises the crucial role that process oils play in your products and operations. We also understand that the quality of these vital oils is paramount, and that using a process oil that has a highly consistent quality can have a major bearing on the success of your business.

Customers in a variety of industries have unlocked value by using Shell Process oils. These include manufacturers of crop protection spray oils, defoamers, explosives, fertilisers, hot-melt adhesives, optical cable fill gels, petroleum jelly, textile and leather auxiliaries, thermoplastic elastomers.

If you are interested in unlocking valuable performance advantages, talk to us about the benefits that Shell Process Oils could have for your business: our experienced process oils experts can work with you to analyse your needs and propose solutions.

The result? Technology that delivers value to your operations.