The history of fuel

Learn all about the development and improvement of fuel over the past 100-plus years. From kerosene manufacturing to today's high-octane performance fuel, Shell takes you on a journey through time.

The conception and subsequent development of the motor car in the past 100 years has been a significant contributing factor to the tremendous economic growth of the industrialised world. The development of the car is primarily due to the invention of the internal combustion engine. But also to the fact that volatile fuels based on hydrocarbons are particularly suitable for running car engines and that the oil industry has been able to produce these fuels in adequate, economic quantities and with constantly improving qualities.

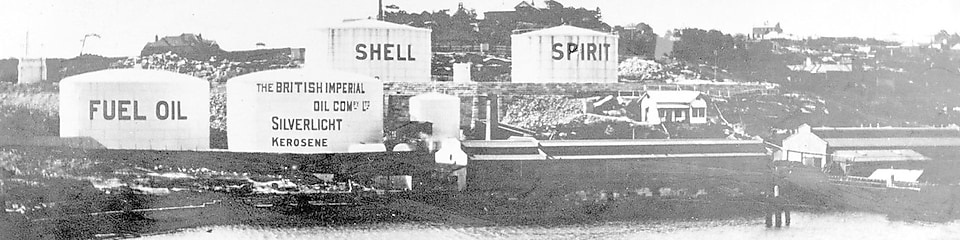

In the late 19th Century the most suitable fuels for the automobile were coal tar distillates and the lighter fractions from the distillation of crude oil. Petrol was used as the fuel for the first four-stroke cycle spark-ignition engine in 1884. Petrol was, at that time, considered to be an undesirable by-product of kerosene manufacturing.

From 1900 to 1920, there was an increase in demand for petrol and it ceased to be just a by-product and the more volatile fractions of kerosene were diverted to petrol. During the early 20th Century the oil companies were producing petrol as a simple distillate from petroleum, but automotive engines were rapidly being improved and their fuels needed to improve with them.

Thermal cracking was introduced in 1913 to convert a larger fraction of petroleum into petrol. Earlier investigations had shown that the heating of crude oil or certain fractions caused a split-up of molecules and thus increased the proportion of volatile fractions suitable for petrol manufacture.

Thermal cracking required elevated pressure for the process. In the 1920's, it was found that certain silica/alumina-based catalysts accelerated the reaction rate to the extent that high pressure became unnecessary. The advantages of catalytic cracking over thermal cracking were a higher petrol yield and a better quality of product.

Lead was first used as an anti-knock agent in 1926. The greater breakthrough in catalytic cracking came when the initially developed fixed-bed catalytic process was replaced by the fluid-bed catalytic process. The fluid-bed process allowed for excellent control of temperature and reaction, which permitted better yields of petrol from the refineries.

The introduction of the catalytic cracking process and catalytic reforming in the 1940's was significant for the manufacture of high-octane petrol components. The 1950's saw the start of the increase of the compression ratio in engines, requiring higher octane fuels. Octane ratings, lead levels, and vapour pressure increased. Minor improvements continued to be made to petrol formulations to improve yields and octane until the 1970s - when unleaded fuels were introduced to protect the exhaust catalysts that were being introduced for environmental reasons.

From the 1970's until 1990 petrols were slowly changed as lead began to be phased out, lead levels plummeted and octane ratings initially decreased, and then remained 2 to 7 numbers lower.

More in Shell fuels

Shell fuel price

Shell understands your fuel-pricing concerns, so here’s a breakdown of the key elements that determine the price at the pump.